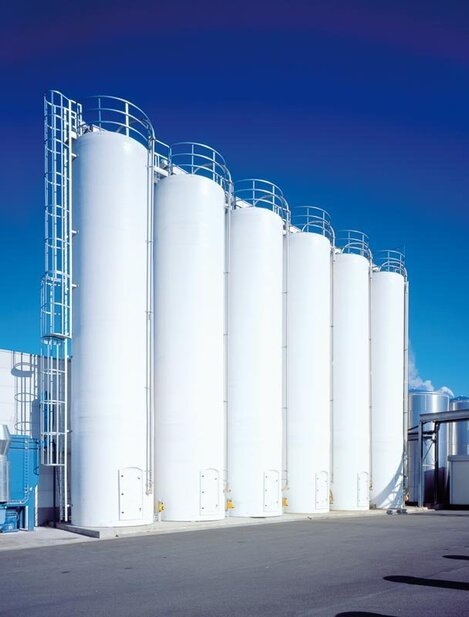

Applications and customers rightly impose high demands on our tanks and silos. Corrosive or even highly hazardous substances are often involved. The stringent requirements applicable to storing foodstuffs require specific solutions. Producing to the highest industry standards is therefore crucial for M.I.P.

Industry

Our installations meet industry standards

Every M.I.P. storage system complies with the standards and guidelines prescribed in, among others, DIN 18820 for composite, EN 13121 for tanks and EN 1090 1 and 2 for steel for the metal underframe.

If desired, our storage systems comply with the ATEX guideline and are always supplied with a declaration of conformity confirming that they are produced according to the applicable European rules. Where applicable, our tanks and silos can be supplied in different fire classes and meet international static approvals.

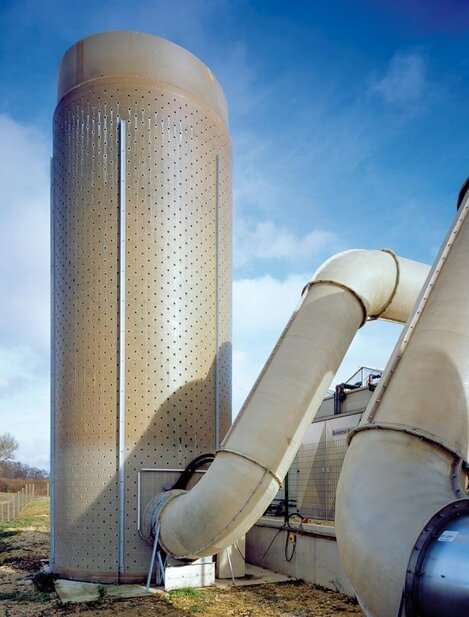

Composite in the industrial sector

Composite storage systems are perfect for industrial and environmental applications, because composite does not rust and is resistant to most corrosive chemical products. Moreover, glass fibre reinforced plastic is anti-static and non-sparking, qualities that are indispensable, for example, for underground and offshore applications. The insulating effect of composite means that dry substances that are sensitive to moisture are best stored in composite silos. Proof of this are the many silos being used, for instance for cement and chalk, yet also for sugar, meal and flour.

Lastly, composite is a very flexible product, which can be produced in almost all possible shapes and dimensions. Coupled with the low weight, this means that composite is highly suitable for customisation and installation in hard to access places or confined spaces, and that modification or repair of existing composite tanks and silos is relatively simple.