Did you know that composite (Fiberglass Reinforced Plastic) tanks are also very suitable for storing products such as hydrochloric acid, citric acid, caustic soda, etc.?

This can be done very well in a single-walled tank, but we can also supply double-walled composite tanks. As a result, an accidental leak of cargo is detected early through continuous leak monitoring.

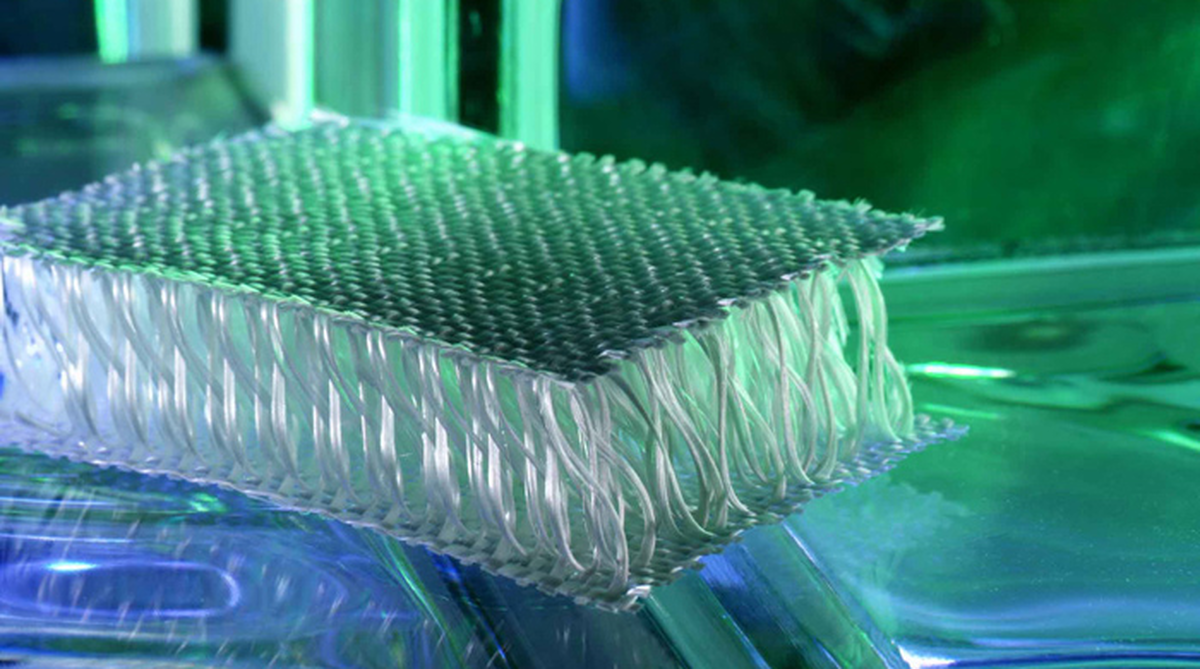

For this intermediate space, M.I.P. use of Parabeam® 3D glass fabric. This is an approx. 4.5 mm thick sandwich element that can be set to over or under pressure.

The Parabeam® 3D glass fabric is placed between the chemical barrier layer and the structural laminate. In this way, the chemical barrier layer is continuously monitored, eliminating chemical attack on the structural laminate. This allows M.I.P. working cost-effectively. After all, a cheap resin of quality can be used for the structural laminate, and a more expensive resistant layer for the chemical barrier layer (which comes into contact with the product).

Which type of resin we should use for this follows from resin advice from our suppliers and partners Polynt and Ineos.