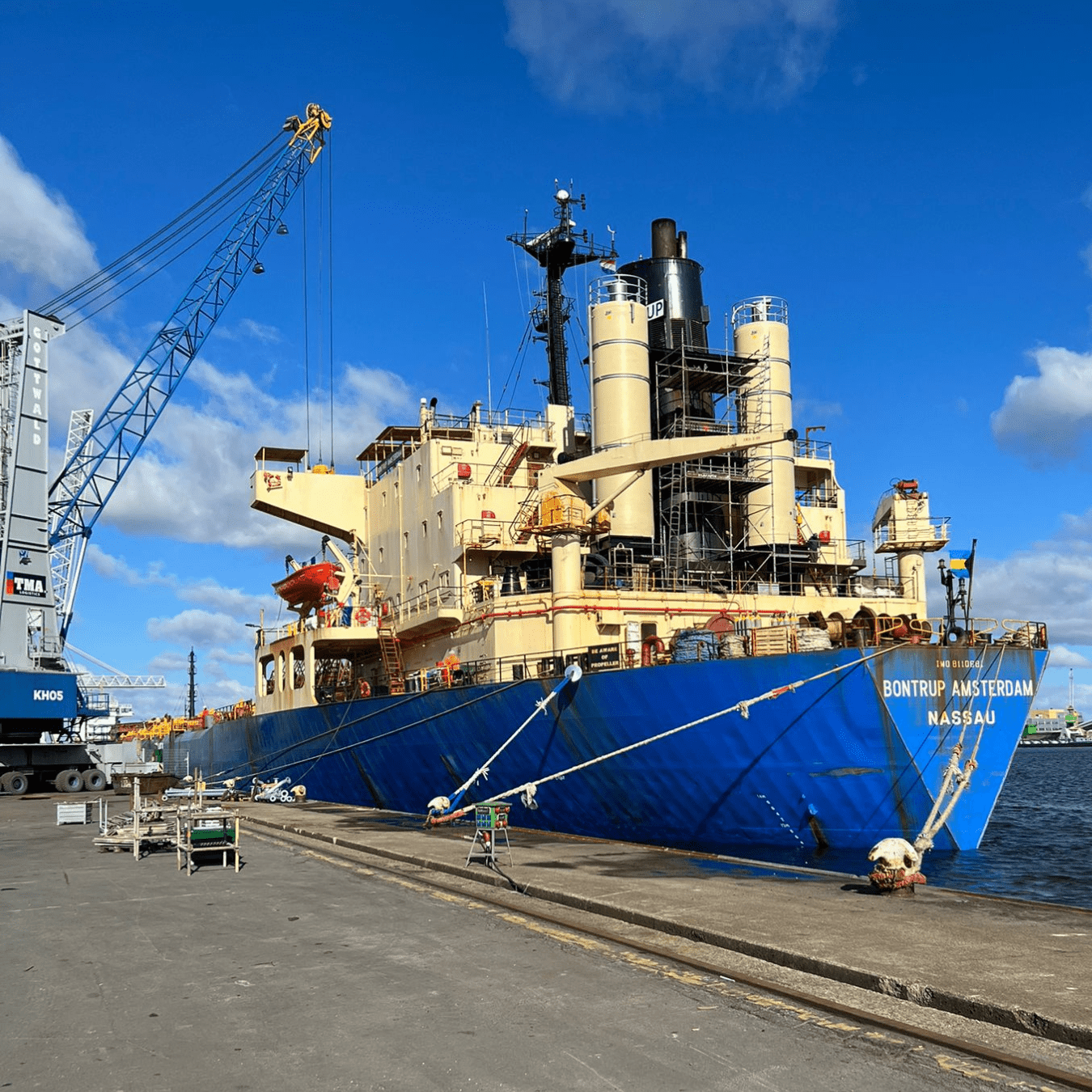

M.I.P. Group provided the bespoke composite silos for the SodaFlexx Integrated Dry Exhaust Gas Cleaning System installed on “Bontrup Amsterdam”, a 65,402 DWT Bulk Carrier. The installation took place in February 2023 in the port of Amsterdam and involved the delivery of two glass fibre-reinforced plastic (GRP) silos 12 m in height and 2 m in diameter as a part of the SodaFlexx EGCS absorbent storage.

SodaFlexx is an equipment innovator for the marine industry and has created a concept to reduce harmful emissions from ships with sodium bicarbonate powder, also known as baking soda. The technology is adopted from land-based power plant applications, where the sulphur is chemically absorbed and changed into sodium sulphate, a highly stable and non-harmful salt. The system is certified by the major shipping classification societies and meets high-quality standards, and it allows ships to use High Sulphur Fuel Oil (HSFO) and be compliant with emission requirements.

M.I.P. composite storage silos offer the following advantages over traditional metal construction:

- Lightweight

- Flexible sizing

- No corrosion

- Fast manufacture

- Low co-efficient of thermal conduction

- No condensation

M.I.P. silos are made of an advanced composite and have a number of properties that offer clear advantages over traditional materials such as aluminium, mild or stainless steel. It is about 60-75% lighter than steel, and it is many times stronger. The glass-resin ratio results in a light material that has extremely high stiffness and tensile strength and can handle high bulk weights.

“In order to optimise the storage conditions and system weight for this installation, we elected to use GRP construction over steel. The major benefits of GRP vs steel are the weight savings which is critical when adding additional equipment to an existing vessel for stability reasons. Secondly and equally important, the GRP storage solution provides superior storage conditions compared to steel storage silos, as the insulation value of GRP is much higher than steel. This higher insulation value ensures stable conditions for the absorbent and avoids condensation. Last, and certainly not least, the flexibility and short production times that M.I.P. was able to meet established that GRP construction is highly preferred for our technology,” – commented Sander Castel, the Chief Technical Officer at SodaFlexx.

M.I.P. is the supplier of bespoke storage systems in composite (glass fibre reinforced plastic, GRP). We offer total solutions for the storage of complex liquids and moisture-sensitive solids. We are very happy to complete this project with SodaFlexx as a part of the long-term cooperation between our companies. We focus on providing sustainable solutions for many industries and cooperation with the shipping industry is a very important part of our business.